Introduction

Manufacturers and suppliers are constantly working to improve performance, safety, and efficiency in the fast-paced automotive sector of today, where innovation is the primary driver. The Vehicle Control Unit (VCU), the “brain” in modern automobiles, is at the forefront of these developments. This crucial part maximizes safety and fuel economy while ensuring the smooth integration and operation of vital vehicle systems like steering, braking, and propulsion.

As automobiles become smarter and more networked, the significance of VCU testing and validation increases dramatically. Therefore, to ensure that modern vehicles meet safety and performance standards, this blog explores the importance, challenges, and processes involved in VCU testing and validation.

The Vehicle Control Unit (VCU): An Overview

Often called the Electronic Control Unit (ECU), the Vehicle Control Unit (VCU) is a sophisticated electronic system in charge of managing several vehicle subsystems. It gathers and analyzes information from a number of sensors, such as those that track engine performance, braking pressure, and wheel speed. The VCU uses this information to make decisions in real-time to increase safety, boost vehicle performance, and cut fuel use.

In order to preserve stability and safety, the VCU, for instance, evaluates data from the brake pressure sensor and triggers devices like the Anti-lock Braking System (ABS) when a driver applies the brakes abruptly. The necessity of thorough VCU testing and validation to guarantee dependability in all situations is highlighted by such complex decision-making.

The Value of VCU Testing And Validation

The three guiding principles of the automotive industry are performance, efficiency, and safety. The following crucial elements are addressed by VCU testing and validation to guarantee that these objectives are fulfilled:

1. Ensuring Security and Safety

When it comes to car design, safety comes first. VCUs manage vital systems like:

Anti-lock Braking Systems (ABS): Wheel lock-up after abrupt braking is avoided with anti-lock braking systems (ABS).

Traction Control Systems (TCS): By controlling wheel slides, traction control systems (TCS) preserve stability.

Electronic Stability Control (ESC): Assists drivers in keeping control when making sudden turns.

Extensive testing guarantees that the VCU can react to possible dangers in a way that protects both pedestrians and passengers.

2. Adherence to Regulations

Because automotive regulatory agencies enforce strict performance, safety, and emissions regulations, VCU testing is crucial. It ensures compliance with these rules, helping manufacturers obtain the necessary certifications and approvals for market access.

3. Maintaining Dependability under Harsh Circumstances

Since vehicles often operate under challenging conditions such as extreme temperatures, strong vibrations, and electrical disruptions, VCU testing is essential. It ensures consistent performance throughout the vehicle’s lifetime by evaluating the unit’s durability.

4. Improving the Performance of Vehicles

By adjusting variables including power delivery, fuel economy, and drivability, VCUs maximize vehicle performance. Through testing, manufacturers can find and fix inefficiencies, improving the driving experience as a whole.

Challenges in VCU Testing and Validation

Despite the obvious advantages of VCU testing and validation, there are several difficulties with the procedure:

1. Complexity of the System

Since modern automobiles consist of many interrelated systems, each with a distinct function, testing VCUs requires addressing compatibility concerns while ensuring seamless integration with these subsystems.

2. Simulation of the Real World

Replicating real-world scenarios in testing environments presents significant challenges. Therefore, testing VCUs to simulate various driving conditions, traffic patterns, and potential emergencies requires the use of advanced simulation tools.

3. Risks to Cybersecurity

With the rapid proliferation of autonomous and connected cars, cybersecurity concerns have become increasingly serious. Therefore, to ensure protection against cyberattacks that could compromise data security or vehicle safety, VCUs must be thoroughly examined for vulnerabilities.

4. Regular Updates to the Software

Updates are regularly made to automotive software to improve functionality and address issues. These modifications must be taken into consideration during VCU testing to guarantee compatibility with current systems and avoid unforeseen problems.

Important Steps in the Testing and Validation of VCUs

To overcome these challenges, automobile manufacturers implement a variety of testing techniques specifically designed to assess distinct VCU components effectively.

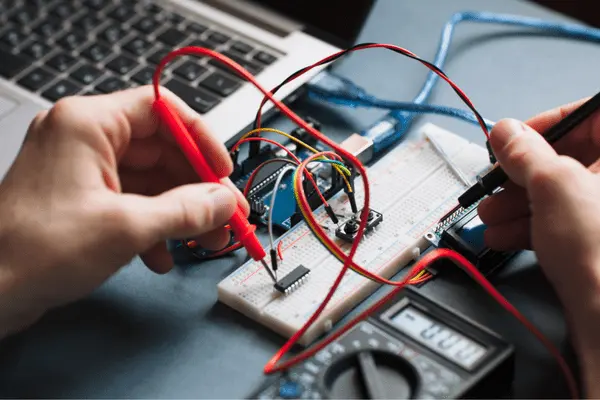

1. Testing of Components

This entails testing separate VCU subsystems to find and fix certain problems before incorporating them into the overall system. Manufacturers can guarantee that every element operates as intended by isolating components.

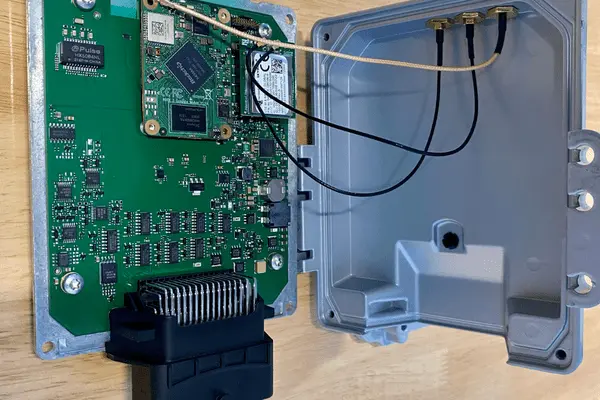

2. HIL or hardware-in-the-loop, Examining

HIL testing, as a crucial validation step, involves connecting actual VCU hardware to a virtual environment that accurately simulates the vehicle’s surroundings. This approach ensures comprehensive performance assessment in a controlled yet realistic setting. As a result, this method allows for a comprehensive performance evaluation in a realistic yet controlled setting. Moreover, HIL testing proves highly beneficial in assessing:

- Reaction to different driving circumstances

- Interaction with other systems

- Managing unforeseen situations

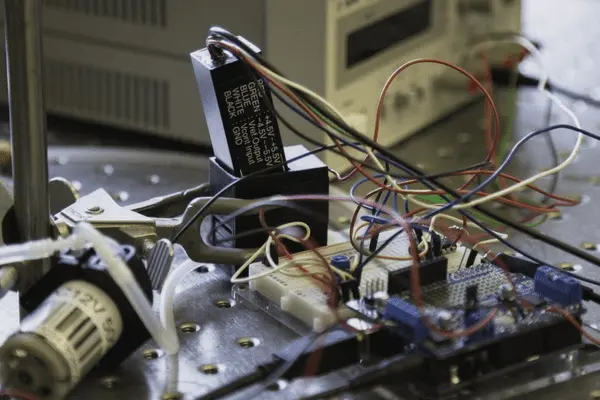

3. SIL, or software-in-the-loop Testing

The team initially assesses VCU software through computer simulations in SIL testing, which eliminates the need for hardware. Consequently, this approach enables rapid iterations and improvements, ensuring that the software meets performance requirements before hardware integration.

4. Testing of Vehicles in the Loop (VIL)

At this phase, to conduct thorough on-road testing, the VCU is first installed in an actual vehicle. This step enables engineers to systematically evaluate its real-world performance under diverse driving conditions, ensuring reliability and efficiency. This method offers insightful information about how well the VCU performs in real-world driving situations, such as:

- Different weather conditions

- Traffic jams

- Emergency handling and braking

Dorleco’s Function in VCU Testing And Validation

Dorleco is a top supplier of automotive solutions with a focus on developing, testing, and validating VCUs. Dorleco guarantees that its products fulfill the highest levels of safety, dependability, and performance thanks to its advanced technology and knowledge of battery-specific requirements.

Conclusion

VCU testing and validation have become increasingly important as automotive technology has advanced. The goal of these procedures is to create safer, more intelligent, and more effective automobiles—not just to guarantee compliance. By tackling issues such as cybersecurity and system complexity, automakers can improve vehicle performance and dependability while safeguarding consumers.

The techniques for VCU testing and validation will develop along with the automobile sector, utilizing cutting-edge technologies to address new problems. These initiatives will guarantee safer roadways, better driving experiences, and an innovative and efficient future.

Contact info@dorleco.com for additional details on Dorleco’s VCU solutions and testing services. Discover our exceptional proficiency in designing and developing reliable, state-of-the-art VCUs, seamlessly tailored to meet your vehicle’s unique requirements.