Introduction

VCU Testing And Validation

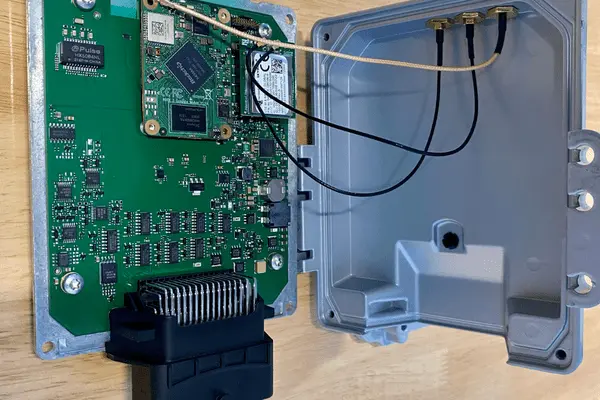

In the rapidly evolving field of automotive technology, manufacturers and suppliers of vehicles are constantly coming up with new ideas to enhance performance, safety, and economy. One of the key components in charge of managing these advancements is the Vehicle Control Unit (VCU). As the brains of the car, the VCU processes data from several sensors and systems to control essential functions, including steering, brakes, and propulsion.

Given the significant hazards involved, the significance of VCU testing and validation in ensuring the dependability and safety of contemporary cars cannot be overemphasized. This blog examines the importance, challenges, and VCU testing and validation methods.

What is a vehicle control unit (VCU)?

The Vehicle Control Unit (VCU), sometimes known as the Electronic Control Unit (ECU), is a vital electronic part that oversees and controls several vehicle subsystems. The vehicle communication unit (VCU) gathers data from various sensors located throughout the vehicle, such as wheel speed, engine, and brake pressure sensors. With the use of this data, the VCU may make snap judgments that improve vehicle performance, safety, and fuel efficiency.

1. The importance of VCU Testing And Validation

VCU validation and testing are crucial processes that guarantee a car will run efficiently and safely. Robust techniques for testing and validation are necessary for the following reasons: Guaranteed security and safety are the top priorities when it comes to autos.

VCU testing ensures that safety-critical components such as anti-lock braking systems (ABS), traction control systems (TCS), and electronic stability control (ESC) function flawlessly. Validation demonstrates the VCU’s ability to react to possible threats in a way that prevents mishaps and safeguards pedestrians and passengers.

- Adherence to regulations: The regulatory bodies overseeing the automotive sector establish stringent emissions, safety, and performance benchmarks. Vehicle compliance testing and validation (VCU) enables manufacturers to obtain the necessary certifications and approvals for their products by confirming that automobiles adhere to these standards.

- Strength and Reliability Modern cars are subjected to harsh environmental conditions and heavy use. VCU testing shows the control unit’s resilience and dependability in the face of extreme temperatures, vibrations, and electrical disruptions, ensuring consistent functioning throughout the vehicle’s life.

- Enhancement of Performance Vehicle performance optimization requires VCU testing. By analyzing data and doing simulations, manufacturers may maximize power delivery, reduce fuel consumption, and enhance overall drivability.

2. Difficulties in VCU Testing and Validation

VCU testing and validation pose several challenges that need to be carefully considered to assure accuracy and efficacy, such as the complexity of the System Modern cars are made up of several interconnected systems, each with a distinct purpose. Testing also includes addressing any potential problems and confirming the VCU’s interoperability with other subsystems.

It might be challenging to replicate real-world situations in simulators of the real world for testing. Complex simulation software and technologies are sometimes required for VCU testing to replicate different driving conditions, traffic scenarios, and potential crises.

As connected cars become increasingly common, worries about cyber security are becoming more and more pressing. VCU testing needs to focus on locating and blocking potential cyberattacks that can compromise data security and vehicle safety. Continual Updates Car software is updated frequently to fix bugs and enhance functionality. VCU testing techniques must take these changes into account to ensure compatibility and simple interaction with the existing systems.

3. Procedures for VCU Testing

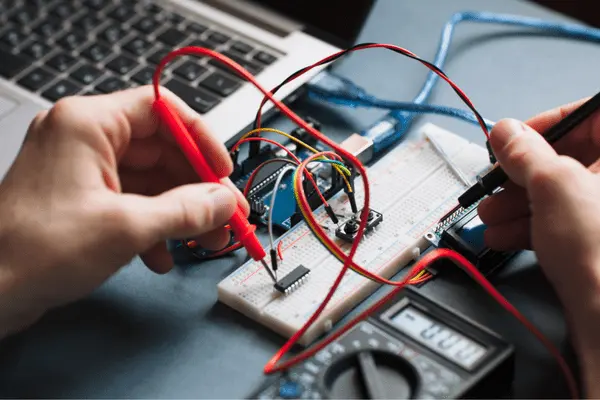

Examination of Components Component testing comprises evaluating the performance of each VCU subsystem separately. Because of this, producers may find and address issues specific to each part before adding them to the system as a whole.

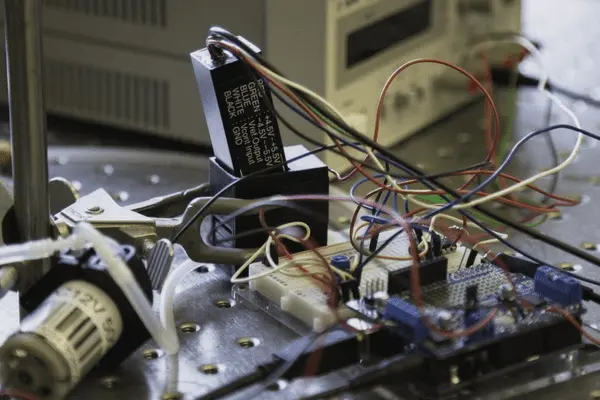

- Hardware-in-the-Loop (HIL) testing. Real VCU hardware components are tested in HIL in synthetic environments that mimic the vehicle’s surroundings. This technique assesses the VCU’s performance in a range of operating conditions while guaranteeing safety in a controlled setting.

- Software-in-the-loop (SIL) testing Software Validation (SIL) testing verifies the VCU’s software performance without utilizing hardware. Computer simulations are used in this testing. The method allows for rapid iterations and refinements of the software before the hardware integration phase.

- Transport-in-the-Loop (TIL), A genuine car is equipped with the VCU as part of the VIL testing procedure. This makes it possible to do extensive real-world testing to evaluate the VCU’s performance in various driving conditions.

Conclusion

In conclusion, VCU testing and validation are crucial processes that guarantee the safe and trustworthy operation of modern cars. Manufacturers invest significant time and resources into these operations to ensure regulatory compliance, enhance performance, and, above all, ensure the safety of drivers, passengers, and pedestrians.

The methodology for VCU testing will progress in tandem with the advancement of automotive technology, incorporating innovative approaches to tackle fresh challenges and enhancing driving safety and efficiency for all.

If you are looking for the best VCU supplier and manufacturer with VCU testing and validation, write to info@dorleco.com to find out more about our software development skills for requirements unique to batteries and explore our best VCU products and services.