Introduction

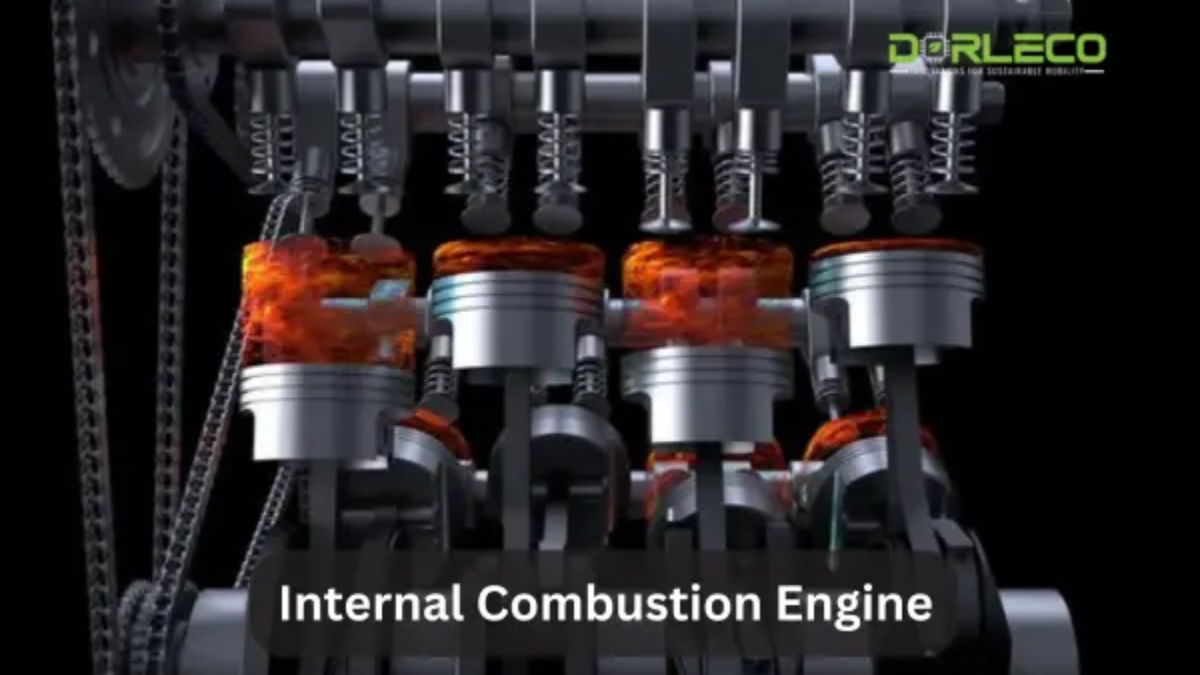

Internal combustion engine (ICEs), which power around 250 million roadway cars in the US alone, have been the foundation of industrial and transportation uses for more than a century. They are a powerful force in the automotive industry because of their durability, driveability, and compatibility with a wide range of fuels, including ethanol, natural gas, propane, diesel, gasoline, and biodiesel. Additionally, they can be included in plug-in hybrid and hybrid systems to improve range and fuel economy. Internal combustion engines are under increased scrutiny because of environmental concerns and the growing demand for greener alternatives, despite their extensive use and benefits.

Internal Combustion Engine Classification

Continuous combustion engines and intermittent combustion engines are the two main types of internal combustion engines that are distinguished by their combustion mechanisms.

1. Engines with Continuous Combustion

Fuel and oxidizer are continuously injected into these engines, maintaining a constant flame. Two of the best examples of continuous-combustion engines that are frequently used in industrial and aerospace settings are gas turbines and jet engines.

2. Engines with intermittent combustion

Conversely, the air-fuel combination is ignited in cycles by intermittent-combustion engines, commonly referred to as reciprocating engines. This group includes diesel and gasoline piston engines, which produce power by burning fuel in precise order.

The Internal Combustion Engine’s Operating Principles

The basic chemical process of combustion, in which fuel and oxygen combine to create energy, is at the heart of internal combustion engines. ICEs use direct fuel combustion to produce energy inside, as opposed to external combustion engines like steam engines.

An ICE is made up of a moving piston and a stationary cylinder. The crankshaft is turned by the piston’s movement, which is pushed by expanding combustion gases. The powertrain then uses this mechanical energy to drive the wheels of the vehicle.

Currently, there are two main categories of ICEs in production:

Spark-Ignition Gasoline Engines: These engines use a spark plug to ignite a mixture of gasoline and air before compression.

Diesel engines that use compression ignition only compress air before injecting high-pressure fuel, which ignites on its own because of the heat generated during compression.

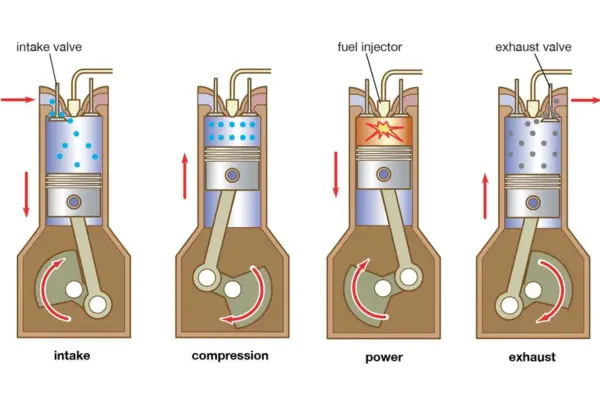

The four-stroke cycle used by the majority of ICEs consists of four crucial stages:

The Cycle with Four Strikes

1. Stroke of Intake: The piston is close to the top dead center (TDC) at the start of the intake stroke. The piston descends as the intake valve opens, bringing in fuel and air (or just air in diesel engines). For the combustion chamber to receive a new charge, this stroke is necessary.

2. Stroke by Compression: The air-fuel mixture is compressed when the piston rises after intake. Because the intake and exhaust valves remain closed, pressure might accumulate. In gasoline engines, the spark plug ignites the fuel-air combination just before TDC, whereas in diesel engines, injecting diesel fuel starts combustion.

3. Power Stroke: The compressed gasses expand violently upon ignition, pushing the piston downward. This stroke produces the engine’s power, transforming heat energy into mechanical work. The power stroke generates energy rather than consuming it, in contrast to other strokes.

4. Stroke of Exhaustion: The exhaust valve opens when the piston reaches the bottom dead center (BDC) following the power stroke. The cylinder releases burned gases through the exhaust system when the piston rises once more.

An engine cycle needs two full crankshaft revolutions (720°), and only one power stroke produces torque; the other strokes use energy.

Internal Combustion Engine Components

Important elements of an ICE consist of:

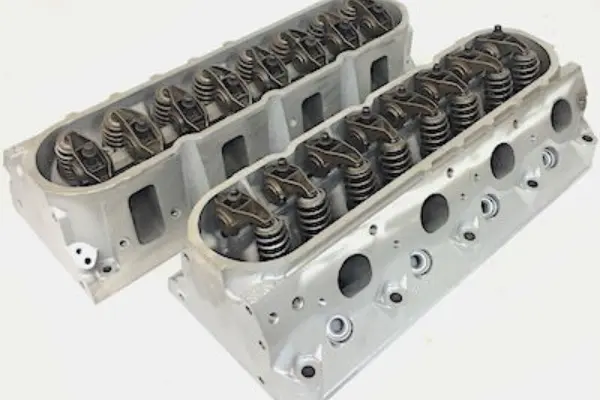

- Cylinder Head: The camshaft, valves, valve buckets, return springs, spark plugs for gasoline engines, and fuel injectors for direct injection engines are all housed in the cylinder head. Additionally, it has engine coolant tubes.

- Engine Block: The crankshaft, connecting rods, pistons, and cylinders make up the engine block. To regulate temperature, it also makes coolant flow easier.

- Combustion Chamber: The combustion chamber is the area between the piston, cylinder head, and engine block where air-fuel combustion takes place.

Internal Combustion Engine Benefits

- Compact Size: Internal combustion engines (ICEs) are substantially smaller than external combustion engines.

- High Power-to-Weight Ratio: They are appropriate for transport applications due to their high power-to-weight ratio.

- Portability: the ability to fit a variety of vehicles and allow for easier carrying.

- Fast Start Time: Internal combustion engines (ICEs) may start nearly instantly, in contrast to steam engines.

- More Efficiency: Compared to external combustion engines, it offers higher efficiency.

- Reduced Maintenance: Needs comparatively less care.

- Lower Lubricant Consumption: Lubrication is more effective than in external combustion engines.

- Moderate Operating Temperature: In contrast to steam engines, internal combustion engines’ maximum temperatures only last a brief period.

Internal Combustion Engine Drawbacks

ICEs have significant disadvantages despite their benefits:

- Limited Fuel Options: Rely on premium gaseous or liquid fuels.

- High Fuel Costs: When compared to alternative energy sources, gasoline and diesel are more costly.

- Environmental Issues: Compared to external combustion engines, internal combustion engines emit more pollutants.

- Noise pollution: reciprocal engines produce a lot of noise during burning.

- Power Restrictions: Not recommended for applications requiring a lot of power.

Internal Combustion Engine Applications

Many industries make extensive use of ICEs.

- Gasoline Engines: Automobiles, boats, and airplanes all use gasoline engines.

- Industries use gas engines to generate electricity.

- Diesel engines power large machinery, trucks, ships, and railroads.

- Industrial, maritime, and aviation settings employ gas turbines.

Internal Combustion Engines’ Future

Cleaner alternatives are becoming more and more necessary as environmental concerns and resource depletion become more urgent issues. Even with notable improvements in ICE efficiency and emissions management, their dependence on fossil fuels continues to be a major drawback.

To overcome these obstacles, research and development initiatives concentrate on:

- Alternative Fuels: Sustainable substitutes include hydrogen, biofuels, and synthetic fuels.

- Electrification: hybrid and plug-in hybrid technologies integrate electric motors to lower pollution and fuel consumption.

- Advanced Engine Management Systems: Control systems powered by AI increase productivity.

- Lightweight Materials: Better materials contribute to a lighter engine, which improves fuel economy.

- Aerodynamic Enhancements: Improving a car’s aerodynamics helps it use less fuel.

Conclusion

Internal combustion engines have greatly aided modern industries and transportation. They are essential because of their success, reliability, and adaptability. However, ICEs need to change to be relevant as the world moves toward greener energy alternatives.

As ICE technology advances, attention is turning to more environmentally conscious options. Electric powertrains, hybridization, and advanced fuels are shaping the future of transportation. The long-term sustainability of internal combustion engines will depend on how well we balance environmental responsibility and energy efficiency. The secret to guaranteeing a sustainable and effective future in industry and mobility is to embrace innovation.