Introduction

In the United States, internal combustion engines power almost 250 million highway vehicles due to their exceptional longevity and drivability. They can run on renewable or alternative fuels in addition to gasoline or diesel (e.g., natural gas, propane, biodiesel, or ethanol). Additionally, they can be paired with plug-in hybrid electric systems to increase the range of hybrid electric vehicles or with hybrid electric powertrains to improve fuel efficiency.

Internal combustion engines are divided into two groups:

Continuous combustion:

Engines with both intermittent and continuous combustion. Fuel and oxidizer enter the engine steadily, which is the hallmark of a continuous-combustion engine. An engine (such as a jet engine) maintains a steady flame.

Intermittent-combustion engines:

The air and fuel in an intermittent combustion engine ignite periodically, giving rise to the term “reciprocating engine.” A cycle is used to process discrete amounts of fuel and air. Examples of this second type are diesel engines and gasoline piston engines.

A sequence of thermodynamic events can be used to describe internal combustion engines. Thermodynamic processes take place concurrently in a continuous-combustion engine as the fuel, oxidizer, and combustion products move through the engine in a steady flow.

In contrast, all of the events in an intermittent combustion engine happen one after the other and are repeated throughout each cycle.

Internal combustion engines consume air, compress it, and either introduce fuel into the air or compress the air-fuel combination. Rockets are an exception to this rule, as they use both liquid-propellant and solid rocket motors.

The air-fuel mixture is then burned, work is obtained from the expansion of the hot gaseous combustion products, and finally, the combustion products are discharged through the exhaust system, as is the case with all internal combustion engines.

Their functioning can be compared to that of external combustion engines (such as steam engines), where energy is obtained exclusively by heat transfer to the working fluid via a heat exchanger and no chemical reaction occurs in the working fluid.

The four-stroke, gasoline-powered, homogeneous-charge, spark-ignition engine is the most widely used internal combustion engine. This might be attributed to its exceptional performance as a leading player in the ground transportation sector.

The aeronautics industry uses spark-ignition engines as well, but because of its focus on range, speed, and passenger comfort, aircraft gas turbines have emerged as the industry’s main players.

Exotic systems including advanced rocket engines and motors, like those found on U.S. space shuttles and other spacecraft, and supersonic combustion ramjet engines (scramjets), like those envisioned for hypersonic aircraft, are also included in the category of internal combustion engines.

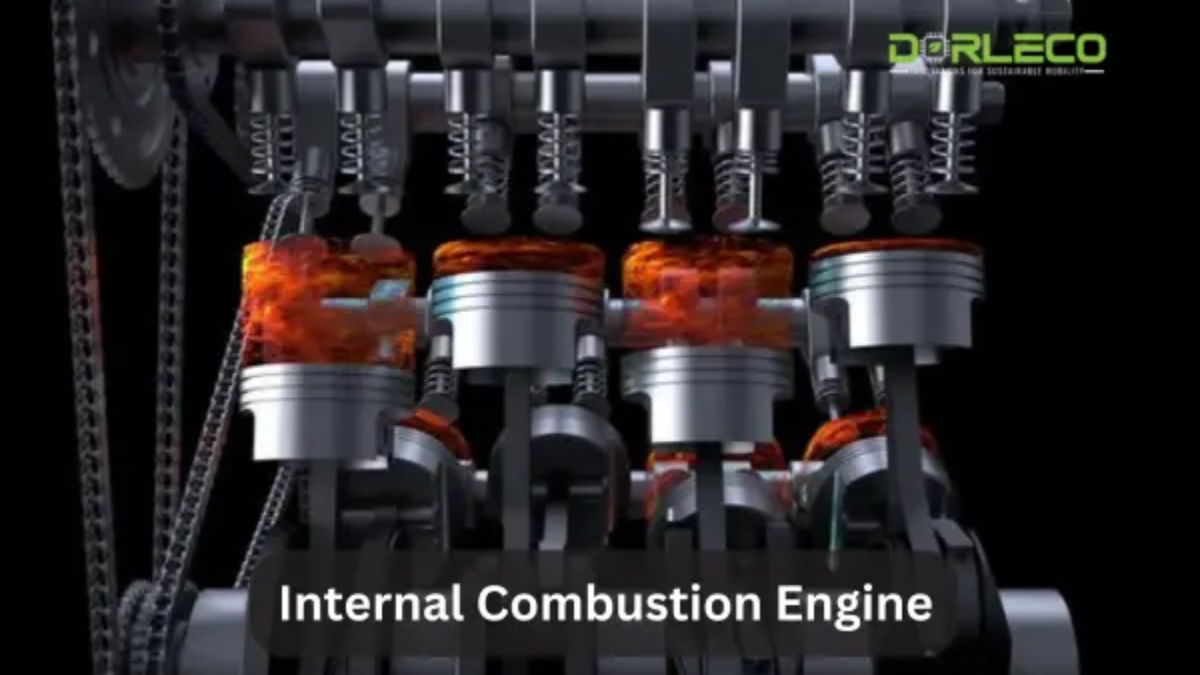

How Does An Internal Combustion Engine Work?

The fundamental chemical process of releasing energy from a fuel and air mixture is called combustion, or burning. The process of fuel ignition and combustion in an internal combustion engine (ICE) takes place inside the engine. After that, the engine uses a portion of the energy produced by combustion to power itself. A stationary cylinder and a moving piston make up the engine. The crankshaft rotates as a result of the piston being pushed by the expanding combustion gasses. In the end, this action turns the wheels of the car through a set of gears in the powertrain.

The spark-ignition gasoline engine and the compression-ignition diesel engine are the two types of internal combustion engines that are currently in production. The majority of these are four-stroke engines, which require four piston strokes to complete a cycle. The intake, compression, combustion, power stroke, and exhaust are the four independent operations that make up the cycle.

The methods used by compression ignition diesel engines and spark ignition gasoline engines to feed and ignite fuel are different. During the intake phase in a spark ignition engine, fuel and air are combined and then forced into the cylinder. The fuel-air mixture is compressed by the piston and then ignited by the spark, leading to combustion. During the power stroke, the piston is pushed by the combustion gasses’ expansion. Only air is introduced and subsequently compressed into an engine in a diesel. The fuel then ignites when diesel engines spray it into the hot compressed air at a proper, controlled rate.

In essence, an internal combustion engine converts the air-fuel mixture’s heat energy into mechanical energy. The reason it is named Four Strokes is that a full combustion cycle in the piston requires four strokes to complete. An internal combustion engine, sometimes known as an ICE (internal combustion engine), is a four-stroke piston engine that powers a passenger car.

Let’s now investigate which constitutes an ICE’s principal parts.

The camshaft(s), valves, valve buckets, valve return springs, spark/glow plugs, and injectors (for direct injection engines) are typically located in the cylinder head. The engine’s cooling liquid passes via the cylinder head.

We can locate the piston, connecting rod, and crankshaft inside the engine block. Regarding the cylinder head, coolant passes through the engine block to assist in regulating the engine’s temperature.

From BDC to TDC, the piston travels inside the cylinder. When the piston is near TDC, a volume is formed between the cylinder head, engine block, and piston. This space is known as the combustion chamber.

An ICE with four strokes has the following phases (strokes) in a complete engine cycle:

Intake power (expansion) exhaust compression intake The piston’s movement between the bottom and top dead centers is referred to as a stroke.

Now that we are aware of an ICE’s constituent parts, we can investigate the actions that take place throughout each engine cycle stroke. The position of the piston at the start of each stroke and the specifics of what happens inside the cylinder are displayed in the table below.

Stroke 1 – INTAKE

The piston is near TDC at the start of the intake stroke. When the intake valve opens, the piston advances in the direction of the BDC. A mixture of air and fuel is pulled into the cylinder. Since new air or mixture is introduced into the engine during this stroke, it is named INTAKE. When the piston reaches the BDC, the intake stroke is over.

The engine uses energy during the intake stroke because the components’ inertia causes the crankshaft to rotate.

Stroke 2 – COMPRESSION

After the intake stroke is complete, the piston begins the compression stroke at BDC. The intake and exhaust valves close during the compression stroke, and the piston travels toward TDC. The air/mixture is compressed when both valves are closed, and when the piston approaches TDC, the pressure reaches its maximum.

During the compression stroke, just before the piston reaches TDC (but not quite there),

Spark is produced in gasoline engines, and fuel is injected in diesel engines.

The engine uses more energy during the compression stroke than the intake stroke since the crankshaft is spinning because of the components’ inertia.

Stroke 3 – POWER

When the piston reaches TDC, the power stroke begins. The intake and exhaust valves remain closed. After the compression stroke, the air-fuel mixture began to burn, which significantly increased the pressure inside the cylinder. The piston is forced downward and toward the BDC by the internal pressure of the cylinder.

The engine creates energy only while it is in the power stroke.

Stroke 4 – EXHAUST

After the power stroke is over, the exhaust stroke begins with the piston at the BDC. There is an open exhaust valve during this stroke. Most of the exhaust gasses are forced out of the cylinder and into the exhaust pipes by the piston’s movement from the BDC to the TDC.

The engine uses energy during the exhaust stroke because the components’ inertia causes the crankshaft to rotate.

As you can see, the piston needs to make four strokes to complete a combustion (engine) cycle. This indicates that two full crankshaft revolutions (720°) are required for one engine cycle.

The power stroke is the only one that generates torque, or energy; all other strokes are energy-consuming.

Advantages of internal combustion engines

- Engine size is extremely small in comparison to external combustion engines.

- The power-to-weight ratio is elevated.

- Excellent for applications with low power requirements

- Typically, more transportable than external combustion engines of the same kind

- safer to use with a much shorter start time

- Higher efficiency compared to an external combustion engine

- There is no possibility of working fluid leaks

minimal upkeep is necessary - Compared to external combustion engines, there is a reduction in lubricant use.

- Because the peak temperature is only achieved briefly (during the fuel’s explosion), the overall working temperature in the case of reciprocating internal combustion is modest.

Disadvantages of internal combustion engines

- The range of fuels available for utilization is restricted to extremely high-quality gaseous and liquid fuels.

- Fuel utilized, such as gasoline or diesel, is quite expensive.

- In general, engine emissions are higher than those of an external combustion engine.

- Unsuitable for producing significant amounts of power

When there is reciprocating internal combustion, fuel detonation produces noise.

Types and applications of internal combustion engine:

- Gasoline engines are utilized in automobiles, boats, and airplanes.

- Gas engines are employed to provide industrial power.

- Diesel engines are utilized in the automotive, railroad, power, and marine industries.

- Gas turbines: They are employed in the maritime, industrial, and aircraft industries.

Conclusion:

To sum up, for more than a century, internal combustion engines have been essential in powering a variety of industry and transportation options. They are essential to contemporary industrialization and mobility because of their effectiveness, dependability, and flexibility. However, the desire to switch to greener, more sustainable options is growing as worries about the effects on the environment and the depletion of resources increase.

Internal combustion engines’ dependence on fossil fuels is still a severe disadvantage, despite notable improvements in efficiency and emissions reduction. Research and development efforts are being directed toward alternative fuels like biofuels and hydrogen, as well as electrification technologies like electric and hybrid powertrains, in an attempt to address these problems.

Moreover, the use of sophisticated engine management systems, lightweight materials, and enhanced aerodynamics keeps improving internal combustion engine performance and fuel efficiency. To combat climate change and lessen reliance on limited resources, a thorough transition to greener transportation options is required.

In conclusion, even though internal combustion engines have proved essential to contemporary transportation and industry, there are growing concerns about their long-term viability. The key to the future is adopting cutting-edge technologies that balance environmental protection with the changing demands of society for dependable and efficient power sources.

Also Read: Things to know about Hybrid Powertrains