Understanding Throttle-By-Wire

The sophisticated electronic control technology known as throttle-by-wire (TBW) is set up in numerous contemporary buses, exchanges, motorbikes, and other motorized vehicles. In discrepancy to conventional mechanical throttle systems, which depend on a factual physical connection between the throttle body and the accelerator pedal, TBW backup’s electronic detectors, and selectors for this mechanical liaison.

Unnaturally, the TBW workshop converts the accelerator pedal input from the motorist into electrical impulses, which are later reused by a vehicle control unit (VCU). To calculate the proper throttle position based on variables including machine speed, cargo, and driving circumstances, the VCU interacts with several detectors located throughout the auto.

Throttle-by-line is one of the technologies that has gained wide acceptance within the automotive sector. Trust ability in enterprises is being raised by mechanical element wear and tear, gash, inefficiency, and growing complexity.

Automakers have started replacing crucial essential rudiments in the traditional vehicle, including the thickets, steering, throttle control, and shifter, with electromechanical or indeed entirely electronic factors. In this essay, we concentrate on” throttle by line” technology. When compared to an electronically controlled steering or retardation system, this is one of the safer designs to use. This system, also called electronic throttle control (ETC), takes the place of the mechanical link that formerly connected the machine’s throttle stopcock and pedal.

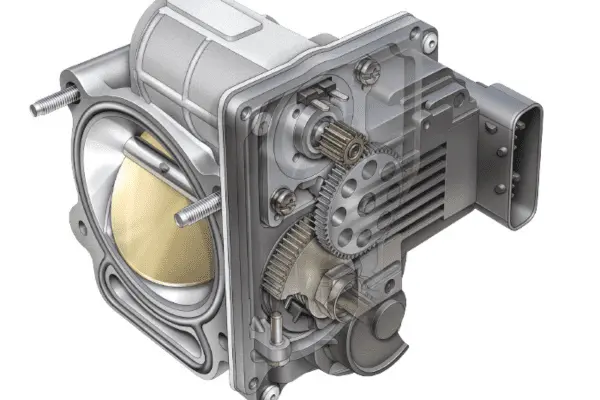

Rather, there are two detectors along with a control unit.

The throttle pedal position detector is the main detector used, and its job is to measure how important it is when the motorist depresses the pedal. This detector may be a resistive position detector or a pressure detector.

The vehicle control unit (VCU) receives the gathered data, computes the necessary energy or current, and also sends this information to the Electronic Throttle Control (ETC) system. The control unit also controls how important the throttle stopcock is in response to the motorist’s requests for acceleration.

There is also another detector that keeps an eye on the throttle opening and feeds back information to the regulator so that commands to open the throttle stopcock are accurate. The pinion gear, intermediate gear, and sector gear are responsible for controlling the drop from the motor actuation angle to the throttle opening angle. This regulator is generally included within the VCU, and the CAN machine protocol is used to simplify communication between factors.

Advantages compared to mechanical control

By integrating numerous safety measures, an electronic throttle regulator can greatly ameliorate riding dynamics. Electronic throttle control systems can do more than just dissect accelerator pedal impulses, unlike mechanical systems that can modify the throttle based on motorist input.

To help correct motorist crimes and save vehicle stability, they also cover inputs from retarding movements, steering responses, and slipping and gripping the bus. The smooth integration of electronically controlled systems with other vehicle systems is one of the main benefits of these systems over their mechanical counterparts. The electronic throttle control (ETC) is an illustration of this point.

Electronic throttle control makes it easier for automakers to include other systems in the design of the auto, similar to machine operation, traction control, electronic stability control, and voyage control.

Crucial safety features in the electronic throttle regulator

The ETC system includes fail-safes for high reliability; if it detects signal issues, it closes the throttle but keeps the engine running. This safety measure is essential for avoiding unintentional acceleration, which may result in disastrous mishaps. The detector arrangement also has numerous redundancies, with one or more backup detectors allocated to each position. This ensures that a single detector malfunction does not compromise the safe operation of the vehicle.

Likewise, there’s concern about the possibility of mobile phone signals snooping into electronic control and communication systems. It’s essential to duly insulate the distribution of signal frequency for colorful purposes to reduce this threat.

But specialist modes like drag and drift bear certain conditions for throttle and boscage commands. Both commands may be inversely important in drift mode, whereas the throttle command takes priority in drag mode. When the motorist applies pressure to the thickets during an unintentional acceleration, this becomes further pivotal. Electronic links between mechanical parts enable override protocols, enhancing control and productivity.

The throttle position detector plays an essential role in unrestricted-circle control, and several fail-safe measures increase its responsibility. Many OEMs already use this technology, and ongoing research aims to improve its safety and responsiveness.

Future Trends and Innovations in Throttle-By-Wire Technology

As technology advances, we expect throttle-by-wire systems to evolve with new features and integrations.

- Integration with Autonomous Driving Systems

Throttle-by-wire technology plays a key role in autonomous driving by facilitating seamless vehicle control.

- Sustainability and Environmental Impact

Efforts to improve fuel efficiency and reduce emissions are driving innovations in throttle-by-wire technology.

- potential for Customization and Performance Tuning

Enthusiasts can explore tuning options to modify throttle-by-wire systems for enhanced performance, always considering safety implications.

Summary

Throttle-by-Wire technology has revolutionized the automotive industry, offering precise control and enhanced driving experiences. Understanding its functions, safety measures, maintenance procedures, and future developments is crucial for drivers and enthusiasts alike.

Development of Throttle-by-Wire Controls at Dorleco

Our main goal at Dorleco is to advance control sense by exercising a tackle setup that consists of a throttle pedal, a control module, and detectors that are used to describe the position of the pedal as well as the opening of the throttle. We use feed-forward and feedback control methods in tandem to efficiently handle faults and produce extremely accurate labor.

FAQs

1.Do modern vehicles only have throttle-by-wire?

Newer vehicles predominantly use Throttle-by-Wire technology, but some older models may also implement this system.

2. Can engineers modify throttle-by-wire systems for increased performance?

3. Are there any potential drawbacks to using throttle-by-wire technology?

Throttle-by-wire systems, like any electronics, can fail; regular maintenance and troubleshooting are key.