Introduction

The process of creating and refining the parts and mechanisms in a car that are in charge of producing and transferring power is known as powertrain design. Any vehicle’s powertrain plays a crucial role in determining its overall operation, performance, fuel economy, and emissions. An outline of the powertrain design is provided here:

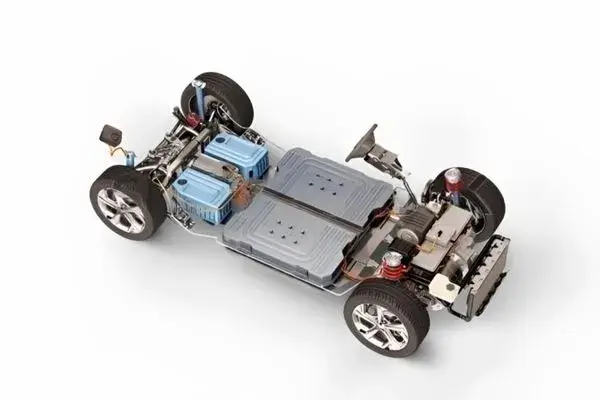

1. Components of a Powertrain:

- Engine: The powertrain’s engine is its central component. By burning fuel and turning it into mechanical energy, it produces power.

- Transmission: Power is distributed from the engine to the wheels by the transmission system. It has many gears to regulate torque and speed.

- Driveline: This system transfers power from the transmission to the wheels and is made up of parts like axles, differentials, and driveshaft.

- Exhaust System: Consists of parts like mufflers and catalytic converters and is in charge of diverting exhaust gases away from the engine and vehicle.

- Engine Control Unit (ECU): Known as the “brain” of the powertrain, the ECU regulates emissions, fuel injection, and ignition timing, among other elements of engine functioning.

2. Design Points to Remember:

- Performance: To achieve the desired performance characteristics of the vehicle, the powertrain design strives to maximize the balance between power, torque, and fuel efficiency.

- Fuel Efficiency: To cut emissions and running expenses, engineers work to improve the fuel efficiency of powertrains.

- Emissions: A key consideration in powertrain design is adhering to emissions standards. This entails adhering to legal requirements and reducing emissions like NOx and CO2.

- Durability: Powertrains need to be made strong enough to endure frequent use strains and continue to be dependable over time.

- Packaging: To fit all powertrain components, efficient use of space is crucial, particularly in small cars.

3. Powertrain Types:

- Internal Combustion Engine (ICE): Fuelled by gasoline or diesel, internal combustion engines power the majority of automobiles.

- Hybrid: For increased efficiency, hybrid powertrains integrate an internal combustion engine, an electric motor, and a battery.

- Electric: Fully electric cars have no internal combustion engines; instead, they run on electric motors that are fuelled by batteries.

- Plug-in hybrid cars: These cars have a bigger battery that can be charged externally and an internal combustion engine.

4. Advancements in Powertrain Design:

Powertrain components are now lighter and more efficient because of manufacturing techniques and materials developments.

The lowered environmental impact of electric and hybrid drivetrains has led to their increasing popularity.

To incorporate these new features, advanced driver assistance systems (ADAS) and autonomous driving technologies affect powertrain design.

Applications of powertrain design

Powertrain design fulfills numerous vital roles and uses within the automotive and transportation sectors. The following are some important applications and uses of powertrain design:

- Vehicle Propulsion: The primary source of the power and torque required to drive a vehicle is the powertrain architecture. It consists of the drivetrain, engine, and transmission parts that send power to the wheels so the car may move forward or backward.

- Optimizing Performance: A vehicle’s speed, acceleration, and towing capacity can all be improved with the help of powertrain design. Powertrains for high-performance cars, in particular, must be carefully engineered to provide optimal performance.

- Fuel Efficiency: When designing a powertrain, fuel economy is quite important. To minimize fuel consumption and raise the miles per gallon (MPG) of internal combustion engine (ICE) vehicles, engineers strive to optimize the energy conversion efficiency of the powertrain.

- Emissions Control: One of the most important aspects of vehicle emissions control is powertrain design. Engineers strive to minimize dangerous pollutants and adhere to strict emissions rules by streamlining combustion processes and implementing emission control systems.

- Electric and Hybrid Vehicles: As electric and hybrid vehicles have become more popular, electric motors, batteries, and hybrid systems have become more common components of powertrain design. Maximizing electric range, energy efficiency, and regenerative braking capabilities are the goals of these systems.

- Adaptive and Autonomous Vehicles: Technologies about adaptive and autonomous vehicles include powertrain design. To combine advanced driver-assistance systems (ADAS) and autonomous capabilities, these cars might need unique powertrains.

- Customization for Different Vehicle Types: The design of a powertrain can be altered to fit a variety of vehicles, such as buses, Lorries, motorbikes, passenger cars, and even recreational vehicles. Every type of vehicle has specific needs for its powertrain to fulfill its intended function.

- Sustainability and Environmental Considerations: The development of environmentally friendly and sustainable automobiles depends heavily on powertrain design. The goals of engineers are to move toward electric and hydrogen fuel cell technologies, decrease carbon emissions, and increase fuel efficiency.

Challenges faced during powertrain design

The process of designing a powertrain requires combining many different parts and systems to produce a dependable and efficient power source for automobiles, which makes it difficult and complex. When designing a powertrain, engineers, and designers must overcome several obstacles. Among the principal difficulties are:

- Emissions and Environmental Laws: One of the main issues in powertrain design is adhering to strict emissions requirements and environmental laws. It’s difficult to reduce dangerous emissions like NOx and CO2 while still operating at peak effectiveness and performance.

- Fuel Efficiency: It’s a continuous challenge to design powertrains that achieve excellent fuel efficiency without sacrificing performance. Reducing operating expenses and environmental effects requires fuel economy.

- Electrification: As electric and hybrid cars become more and more common, combining electric drivetrains, batteries, and related components is a complex process that calls for specific design expertise.

- Component Integration: To guarantee effective power transfer and decreased friction losses, the engine, gearbox, exhaust system, and driveline must all be coordinated with precision.

- Advanced Materials and Manufacturing: Using advanced materials and manufacturing techniques, such as additive manufacturing, lightweight metals, and composites, might provide budgetary and operational difficulties.

- Supply Chain and Budgetary Restrictions: Obtaining parts and supplies while keeping costs down is a big task. Furthermore, changes in commodity prices may have an impact on how affordable powertrain components are.

- Adaptation to New Technologies: Powertrain design must keep up with the rapid advancements in technology, such as connectivity, electrification, and autonomous driving features.

- Adherence to Safety Standards: Observing safety rules poses extra difficulties and needs to be taken into account, particularly when it comes to electric powertrains with high-voltage systems.

Conclusion:

In conclusion, powertrain design is a pivotal aspect of the automotive and transportation industries, influencing the performance, efficiency, and environmental impact of vehicles. It encompasses a wide range of components and systems, including engines, transmissions, drivetrains, and emissions control, each contributing to the overall function and character of a vehicle.

The importance of powertrain design lies in its ability to address key challenges, such as meeting stringent emissions standards, improving fuel efficiency, and adapting to the ever-evolving landscape of electric and hybrid technologies. It also plays a crucial role in enhancing performance, reducing noise and vibration, and ensuring the reliability and safety of vehicles.

As the automotive industry continues to evolve, with advancements in electrification, autonomous driving, and sustainability, powertrain design will remain at the forefront of innovation. Engineers and designers will face ongoing challenges and opportunities to create powertrains that meet the needs of consumers, comply with regulations, and contribute to a more sustainable and efficient future of transportation. Whether it’s through the development of electric powertrains, hybrid systems, or advancements in internal combustion engines, powertrain design will play a central role in shaping the vehicles we drive and ride in for years to come.