Introduction

The automotive industry is undergoing a rapid shift due to technological improvements aimed at enhancing vehicle performance and safety. The VCU architecture and components are a noteworthy innovation among these advancements.

The development of advanced sensors, such as wireless communication modules, LiDARs, radars, and camera systems, has led to notable advancements in driver assistance systems and autonomous vehicles in recent years. Long-distance safe travel, fewer collisions, and traffic jams, adherence to traffic laws, and human-free operation are all anticipated features of autonomous cars.

Similar to a human driver, an autonomous car uses sophisticated algorithms to process data about the road conditions and the car itself. For instance, to identify roads with a reasonable margin of error, these systems must use sophisticated measurement tools like cameras and laser sensors to handle difficult situations like rain or wet roads. Furthermore, autonomous cars must use strict ethical considerations in their algorithms to make quick decisions in unexpected situations.

With a focus on its crucial function in contemporary cars, this blog explores the architecture and parts of the Vehicle Control Unit (VCU) for Advanced Driver Assistance Systems (ADAS).

Vehicle Control Units (VCUs): An Overview

An essential part of contemporary automobiles, the Vehicle Control Unit (VCU) regulates several functions. Its main responsibility is to collect, evaluate, and make decisions that maximize efficiency, safety, and performance from the vehicle’s many sensors and control systems. The VCU has a significantly more crucial role in ADAS-equipped cars since it acts as the main center for handling the intricacies of autonomous and semi-autonomous functions.

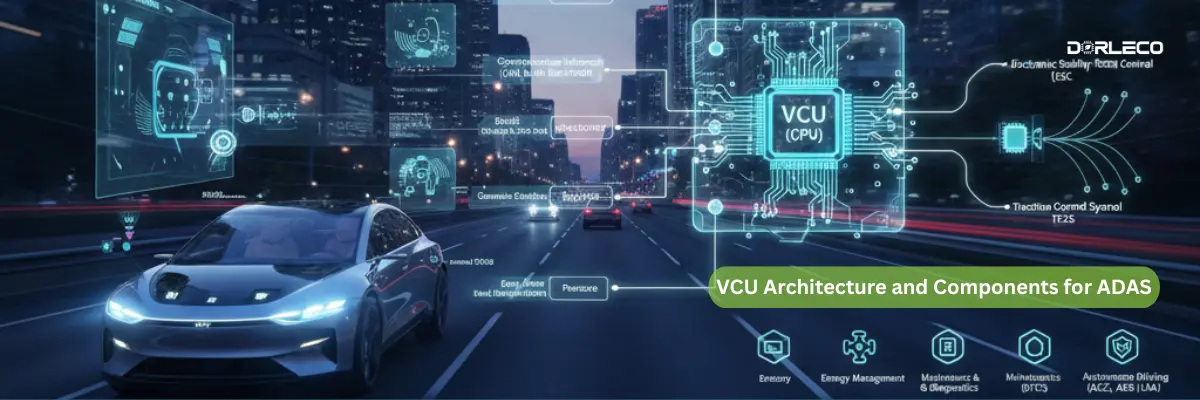

VCU Architecture and Components

The VCU is an advanced hardware and software system that functions in unison to guarantee the vehicle’s safe and effective operation. The following are the main components that make up a VCU architecture and components:

1. CPU, or central processing unit

The CPU functions as the brain of the VCU, processing information and executing commands. Moreover, it performs complex calculations and controls the data flow between the VCU and other components. Thanks to advancements in technology, contemporary CPUs for VCUs can rapidly handle real-time processing needs, which in turn enables prompt and precise decision-making.

2. Recollection

The VCU efficiently stores and retrieves data using a variety of memory types. Specifically, these include ROM for firmware storage, RAM for real-time processing, and flash memory for data logging and updates. This combination ensures both high-speed performance and long-term reliability.

- Random Access Memory (RAM): Data is temporarily stored there while processes are underway.

- The essential firmware and software required for VCU operation are primarily stored in read-only memory (ROM). This ensures reliability and security, as ROM prevents unauthorized modifications while maintaining the integrity of critical system functions.

3. Interfaces for Communication

The VCU connects to sensors and other Electronic Control Units (ECUs) in the car by utilizing various communication protocols. In particular, some of the most common interfaces include CAN, LIN, and Ethernet, all of which ensure efficient and reliable data exchange. As a result, these interfaces enable seamless communication and coordination between different vehicle systems.

- The Controller Area Network (CAN) ensures reliable communication between multiple ECUs.

- Local Interconnect Network (LIN): Manages lower data rates for simpler jobs.

- Ethernet: Facilitates fast data transfer for intricate systems such as ADAS.

4. Sensors

The VCU can make wise judgments based on the real-time data that sensors provide on a variety of metrics. Some of the most important sensors include temperature sensors, speed sensors, and current sensors, all of which contribute to precise vehicle control and optimization.

- Vehicle acceleration is measured by accelerometers.

- Sensors for temperature: Monitor the temperature.

- Position sensors: Monitor the locations of components.

- Data from wheel speed sensors is used to adjust traction and stability.

5. The Actuators

The VCU instructs actuators to change how the vehicle operates. For example, it can adjust throttle response, modify braking force, and regulate battery management to optimize performance and efficiency.

- Engine Control Modules regulate how the engine runs.

- Braking Systems: Modify the amount of force used when necessary.

- Gear shifts are managed by transmission control modules for optimum efficiency.

6. Source of Power

Continuous VCU operation is ensured by a dependable power source, usually the car’s battery. Power management technologies are also incorporated into advanced VCUs to maximize energy usage.

Components and Roles of the VCU

1. ECUs, or electronic control units

The vehicle’s several ECUs work in tandem with the VCU to oversee distinct subsystems, including:

- Engine Control

- Transmission Control

- Anti-lock Braking System (ABS)

- Airbags

The VCU functions as a central coordinator, where it gathers, assesses, and utilizes data from various ECUs. As a result, it ensures seamless communication and efficient control of the vehicle’s electronic systems.

2. Dynamics Management of Vehicles

Controlling the vehicle’s dynamics to improve performance and safety is one of the VCU’s most important roles. Information from sensors such as accelerometers, steering angle, and wheel speed is processed by the VCU to regulate:

- Electronic Stability Control (ESC): Apply brakes to designated wheels to prevent skidding.

- Traction Control System (TCS): During acceleration, the Traction Control System (TCS) maintains the best possible grip.

3. Energy Management

The VCU has sophisticated diagnostic capabilities, enabling it to identify and record system malfunctions. In addition, dashboard notifications and Diagnostic Trouble Codes (DTCs) assist service workers in quickly locating and resolving issues. As a result, maintenance time and costs are significantly reduced.

4. Maintenance and Diagnostics

The VCU has sophisticated diagnostic capabilities, enabling it to identify and record system malfunctions. In addition, dashboard notifications and Diagnostic Trouble Codes (DTCs) assist service workers in quickly locating and resolving issues. As a result, maintenance time and costs are significantly reduced.

5. Assistance for Autonomous Driving

The VCU in cars with ADAS or semi-autonomous features, analyzes information from a variety of sensors, including radar, LiDAR, and cameras. This information makes it possible for:

- Help with lane-keeping

- Adaptive cruise control

- Emergency braking

- Collision avoidance

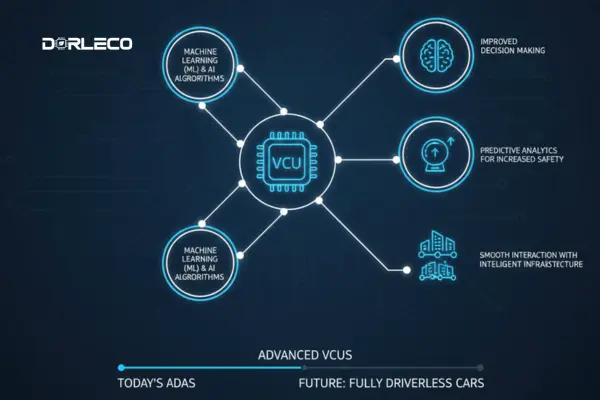

Prospects for VCU Architecture and Components in the Future

As automobile technology develops further, we anticipate VCUs will advance in sophistication. By combining machine learning (ML) and artificial intelligence (AI) algorithms, VCUs will be able to learn and adjust to different driving styles, improving vehicle performance and customization. Additionally, these developments will hasten the creation of completely driverless cars, making it possible for

- Improved ability to make decisions

- Predictive analytics for increased safety

- Smooth interaction with intelligent infrastructure

Conclusion

A key component of contemporary automotive systems, the Vehicle Control Unit (VCU) facilitates smooth communication between numerous sensors and ECUs while overseeing vital operations including diagnostics, energy economy, and vehicle dynamics. A CPU, memory, communication interfaces, sensors, actuators, and power management are all part of its complex design, which guarantees the best possible vehicle performance and safety.

The VCU architecture and components will be crucial in determining how transportation develops in the future as the automotive sector embraces innovation, opening the door for safer, more effective, and ecologically friendly automobiles. Contact us at info@dorleco.com to find out more about Dorleco’s VCU architecture, component design, and software development skills suited for battery-specific applications.