Introduction

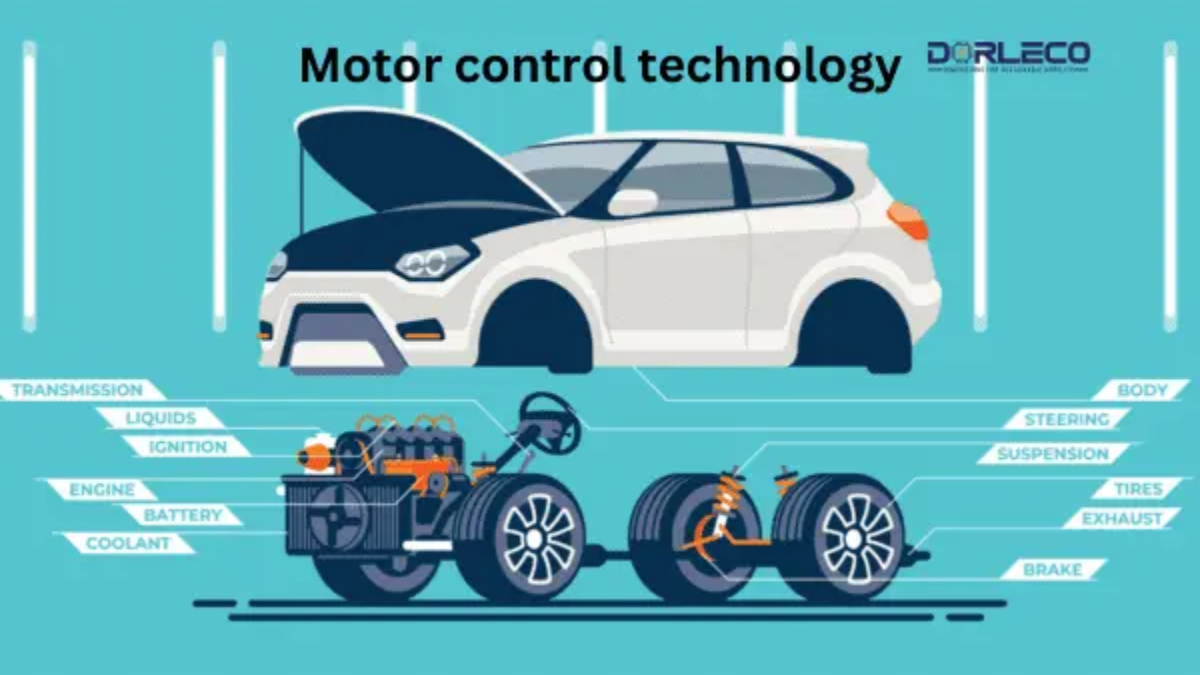

The application of different methods and technologies to coordinate and guide the operation of motors is known as motor control technology. Motors transform electrical energy into mechanical motion. They are extensively utilized in many different industries, including robotics, automotive systems, home appliances, and industrial gear. For motors to operate precisely, effectively, and safely in a variety of situations, motor control technology is essential. Several noteworthy facets of motor control technology include the following:

1. Motor controllers:

Microcontrollers and microprocessors, which execute control algorithms, interpret feedback, and generate signals that move the motor, are the brains behind motor control systems.

In motor control applications, digital signal processors, or DSPs, are widely used to interpret signals in real time and enable faster, more accurate control.

2. Algorithms for Control:

PID Management: A popular algorithm for controlling a motor’s speed, position, or torque is proportional-integral-derivative (PID) control. It adjusts control parameters based on the difference between the desired and actual values.

FOC, or field-oriented control: FOC is widely used in AC motor control to independently manage the torque and flux components to increase performance and efficiency.

3. Sensors:

- Encoders: These devices provide information about the motor’s location, allowing for precise position tracking and control.

- Hall Effect Sensors: These sensors monitor the position of the rotor and turn on the motor windings in brushless DC motors.

4. Electronic Drives:

- Inverters: These devices control the output voltage and frequency while transforming DC power into AC electricity for AC motors.

- Amplifiers: Increase the control signals from the controller to the power levels required by the motor.

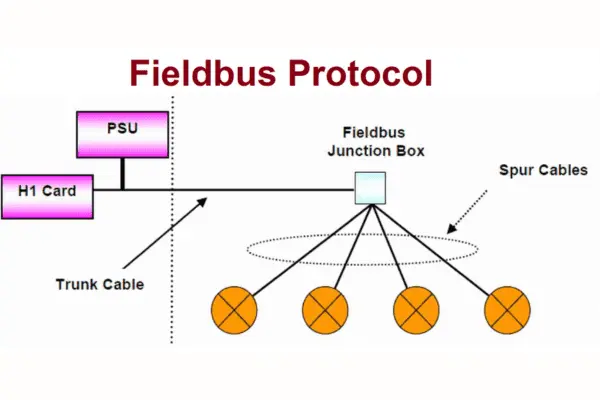

5. Protocols for Communication:

- Fieldbus Protocols: These are used in industrial settings to provide communication between PLCs, motor controllers, and other equipment. Examples of these protocols are EtherCAT, CANopen, and Modbus.

- Ethernet and Wireless Communication: These technologies, which offer advantages like remote monitoring and control, enable communication in networked systems.

6. Power Electronics:

- Power Factor Correction (PFC): Improves the energy efficiency and power factor of the motor control system.

- Variable frequency drives (VFD) and soft starts: By enabling motors to accelerate and decelerate under control, VFDs and soft starters reduce mechanical stress and energy consumption.

7. Enhanced Features:

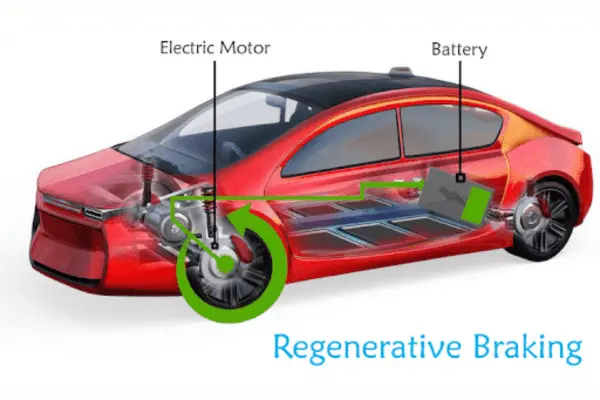

Regenerative braking allows the motor to act as a generator by recovering energy during braking and transferring it back into the power source.

By employing sensors and data analytics to detect possible motor breakdowns, predictive maintenance enables proactive maintenance.

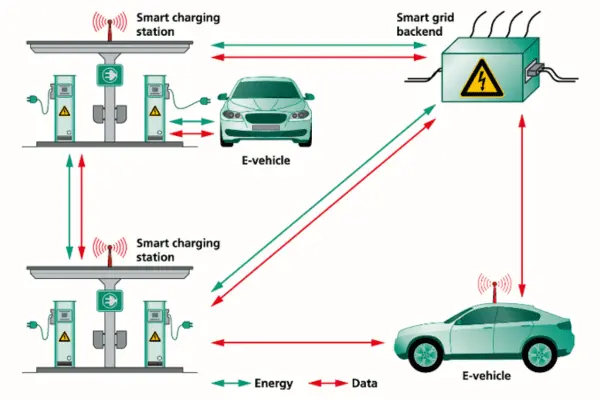

8. Industry 4.0 integrating IoT:

- IoT Connectivity: By connecting motor control systems to the Internet of Things (IoT), it is possible to diagnose, monitor, and control them from a distance.

- Data analytics: Motor performance optimization, efficiency increase, and predictive maintenance.

The advantages of motor control technology

Applications for motor control technology can be found in many different fields. The following are some of the main benefits:

1. Efficiency of Energy Use:

Motor speed, torque, and position can all be precisely controlled by motor control systems, which maximize energy consumption.

Power Factor Correction (PFC) and Variable Frequency Drives (VFDs) are two examples of energy-saving technologies that enhance power factor and adjust motor operation in response to demand.

2. Precision & Accuracy:

Advanced control algorithms such as PID and Field-Oriented Control (FOC) provide precise control over motor parameters, ensuring proper motion and placement in robotics and industrial processes.

3. Improved Results:

The performance of the system is enhanced overall because motor control technology enables smoother acceleration and deceleration and lessens wear and tear on mechanical components.

Faster reaction times and improved dynamic behavior are a result of strong motor control systems.

4. Lower Maintenance Expenses:

Predictive maintenance features, which save maintenance costs and downtime by identifying issues before they lead to equipment failure, are made possible by motor control technology.

Two more elements that increase equipment life and reduce maintenance requirements are soft starts and controlled acceleration and deceleration.

5. Adaptability and Flexibility:

Motor control systems can be employed in situations where the load needs fluctuate because of their flexibility.

Programmable controllers and flexible communication protocols enable easy integration into a wide range of automation systems.

6. Energy Recovery and Regenerative Braking:

Motor control technology can recover energy during braking and deceleration through the use of regenerative braking.

This feature can be particularly useful in situations where stopping is done frequently and contributes to greater energy efficiency.

7. Industry 4.0 Integration and Automation:

Motor control technology is a key component used in Industry 4.0 and smart factory implementations.

Modern communication protocols and data analytics integration assist data-driven decision-making and optimization.

8. Monitoring and Control at a Distance:

Integration with IoT and communication protocols enables remote monitoring and control of motorized systems, enabling real-time diagnostics and alterations.

Remote access facilitates troubleshooting and reduces the need for on-site interventions.

The motor control technology’s shortcomings

Motor control technology has many advantages, but it also has some disadvantages and challenges in its use. Among the principal downsides are the following ones:

1. Price and intricacy:

The intricacy of developing, putting into practice, and maintaining sophisticated motor control systems can lead to higher initial costs.

Because these systems are complex, specialized skills may be required for installation and troubleshooting.

2. Sensitivity to Environmental Conditions:

It is evident how sensitive motor control systems are to many environmental factors, such as temperature, humidity, and pollution. Weather extremes might affect performance and dependability.

3. Electromagnetic interference (EMI) compatibility:

Electromagnetic interference from motor control electronics may affect other nearby electronic devices. Appropriate shielding and filtering are required to lower EMI.

Compatibility issues may arise when integrating motor control systems with machinery or systems that are already in place.

4. Restricted Tolerance to Fault:

Although motor control systems are often equipped with safety safeguards, they may not be as fault-tolerant as they may be. Failed vital control systems may cause unexpected motor action and possibly cause damage.

5. Maintenance Difficulties

Predictive maintenance features do not guarantee against unexpected failures, thus prompt intervention is still necessary.

Certain applications may be concerned about downtime during maintenance, and certain skills may be required for maintenance.

6. Restricted Standardization

Unstandardized communication protocols used by different providers and systems might hinder interoperability.

When attempting to mix parts from multiple manufacturers, integration challenges may come up.

7. The Learning Curve

when using new technologies or control algorithms, engineers and technicians may need to go through a learning curve to deploy and optimize motor control systems.

Conclusion:

To sum up, motor control technology is a revolutionary and transformative force that is reshaping a variety of sectors by enabling us to operate motors more efficiently and intelligently. Automation and industrial processes advance greatly as a result of its many advantages, which include improved safety, precision, and energy efficiency. When combined with predictive maintenance capabilities, the capability to remotely monitor and regulate motors lowers maintenance costs and downtime, promoting a more dependable and sustainable operating environment.

But it’s important to recognize the difficulties with motor control technologies. The intricacy of these systems, possible sensitivity to environmental factors, and compatibility and standards concerns highlight the necessity of meticulous preparation, execution, and continuous upkeep. To guarantee the integrity and security of these vital systems, the integration of motor control systems into the larger Industry 4.0 framework also presents cyber security issues that need to be resolved.

Research and development efforts are being made to further improve the adaptability, robustness, and ease of integration of motor control technology, as well as to mitigate these issues as technology continues to evolve. The continued convergence of technology innovation and real-world application holds the potential to unleash even higher efficiency, opening the door to more intelligent, networked, and environmentally friendly industrial processes. A balanced strategy that takes into account both the benefits and drawbacks of motor control technology navigation will be essential for successful adoption and long-term gains.