FCEVs or BEVs

Introduction

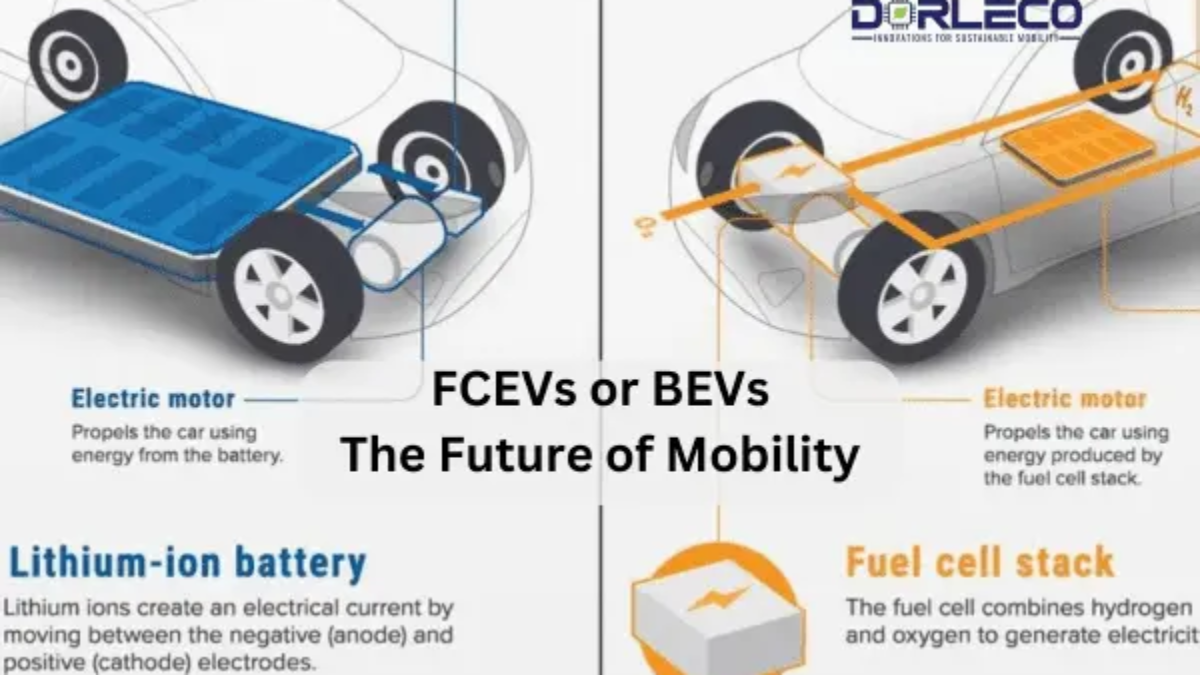

As we already know, automakers are turning to alternative energy sources to power their vehicles due to the depletion of fossil fuel deposits and the negative environmental effects of their combustion. These energy sources must be varied and sustainable, including fuel cell electric cars (FCEVs) and battery electric vehicles (BEVs).

There is much discussion about whether BEVs should take precedence over FCEVs, even if the automobile industry has already begun to look at sustainable alternatives. This is especially true given the finite supply of lithium, a key component of lithium-ion batteries. As a result, a lot of researchers are supporting the use of fuel cells, which use a redox reaction’s chemical reaction to produce energy. However, most automakers are still cautious about using fuel cells in production vehicles since research and development are still being done on how they behave in automotive batteries.

This article aims to address these concerns about the FCEVs or BEVs debate.

The Relationship between FCEVs or BEVs

In this specific argument, a common misperception is that fuel cells and lithium-ion batteries are rival technologies. It’s critical to realize that batteries, as one of the main energy sources, are here to stay in business for a very long time.

Lithium-ion and fuel cell technologies offer a range of solutions to address issues related to sustainability, pollution, and efficiency. These two substances seek to improve the answers to the electrification dilemma that the sector is now dealing with. Fuel cells are expected to complement batteries rather than replace them as the main component of the electrified solution in the future.

Difficulties in the Current Market

when discussing sustainable mobility, range is often the first factor to be questioned, particularly when discussing heavy-duty transportation. Very high-payload capacity combustion engine vehicles often have a big fuel tank, roughly 200–300 liters (50–80 gallons). This frequently enables them to travel 400 miles (depending on the payload) before needing to halt for a fuel stop. But while fuel cells and lithium-ion cells are still in their infancy, none of the technologies has yet been able to match the range requirements of heavy-duty transportation.

Furthermore, a high-capacity battery is probably going to be hefty, which raises the load and thus the energy requirement. For example, the battery in the Hummer EV is expected to weigh the same as the battery in the Honda Civic. High-energy-density batteries, sometimes known as fuel cells, are one way to break this vicious cycle.

Automotive designers will face a unique issue when it comes to heavy-duty transport because there are a lot of trade-offs when adopting Li-ion cells. The maximum permitted weights on each axle are currently capped at a lower level, which forces designers to decrease battery capacity, which reduces range.

It also reduces the amount of load a vehicle can transport on a given trip when the payload capacity is restricted, which is not exactly good logistical economics. Ultimately, automakers will always have to make a trade-off between efficiency and performance.

It is not exactly ideal logistical economics, as it also lowers the amount of load a truck can transport on a given journey when the payload capacity is limited. In the end, automakers will always have to choose between performance and efficiency.

FCEVs or BEVs

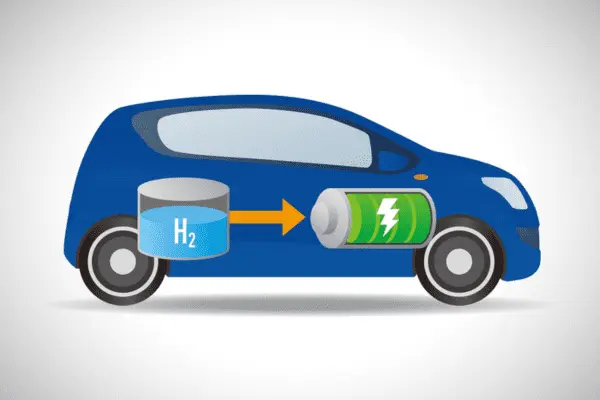

One of the reasons FCEVs presently outperform BEVs is downtime. An internal combustion engine vehicle (ICEV) requires approximately twice as much time to refill as a fuel cell electric vehicle (FCEV), which makes it a desirable option for lengthy road trips.

Creating megawatt-scale charging stations would be the answer to this problem for BEVs. Because drivers can stop as often as necessary for charging, shortening the charging period also enables designers to minimize the size (and weight) of the battery.

The ability to use renewable energy solutions more widely and hasten the adoption of sustainable power sources is another significant benefit of FCEVs. Additionally, they fill in the performance and operational deficiencies in the current batteries. When it comes to driving a style that primarily involves long-distance travel, like commercial vehicles, FCEVs can generally outperform BEVs.

Moreover, fuel cell electric vehicle (FCEV) payload capacity surpasses that of a battery electric vehicle (BEV) due to the fuel cell powertrain’s substantial weight reduction, which permits engineers to enhance the energy capacity without appreciably changing the vehicle’s overall weight. The capacity of a lithium-ion battery to satisfy the powertrain’s dynamic needs is by far its greatest advantage over a fuel cell.

Fuel cells are designed for non-dynamic/static behavior, while numerous combinations for dynamic behavior may be produced at this time. It is hoped that shortly, solid-state cell solutions for mobility will be developed by researchers in the lithium-ion battery business.

So, which is superior in every situation?

The argument over whether BEVs are preferable to FCEVs or vice versa should be seen from a different angle since it comes down to whatever technology is best suited for a certain set of transportation requirements. A greater portion of the industry can be served by BEVs, but sustainable FCEV solutions can address their drawbacks.

FCEVs with lighter powertrains can have greater range since they can hold more energy without adding to their total weight. Fuel cells are an appealing option for heavy-duty and long-distance applications because of their increased payload-bearing capability and faster charging (or refilling) times.

The disadvantage of a fuel cell is that hydrogen requires a lot of energy to produce and store, and fuel cell technology is still in its infancy. This means that fuel cells are more expensive than lithium-ion batteries. Lithium-ion batteries also have far superior dynamic behavior than fuel cells. By no means are BEVs and FCEVs two sides of the same coin. Rather, it is necessary to consider them as two distinct avenues that might be pursued to address the same issue—that is, the difficulties associated with sustainable mobility.

Initiatives for BEV and FCEV at Dorleco

At Dorleco, we create software based on models for battery chemicals and fuel cells. Development-wise, we are focusing on cell balancing algorithms and Kalman filter-based SOC estimate techniques, along with thermal modeling and control of these energy sources.

The focus is on the BMS controller and fuel cell controller integration on a CAN architecture, as well as battery validation and verification using charging and discharging experiments. Using Raptured tools, we can assist you with rapid control prototyping for battery systems as well.

Write to info@dorleco.com to find out more about our software development skills for requirements unique to batteries and explore our best VCU products and services.