Introduction

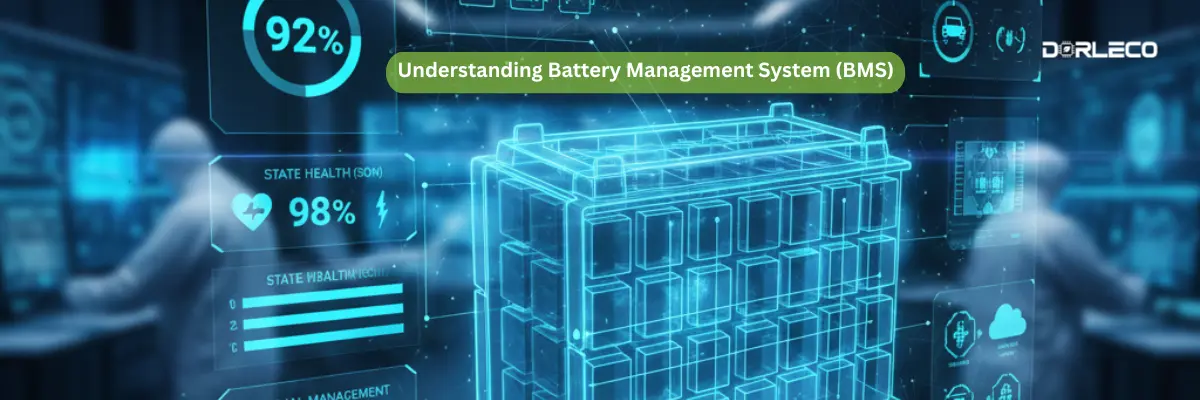

The technology underlying electric cars (EVs) is developing quickly and increasing in popularity. The Battery Management System (BMS) is vital to any energy storage, renewable energy, or electric vehicle system. By keeping an eye on and controlling many facets of the battery’s condition and operation, a BMS guarantees the battery pack’s best performance, longevity, and safety. We will explore the fundamental ideas of BMS in this blog, including its operation, its main components, and the range of tasks it carries out.

What is a Battery Management System?

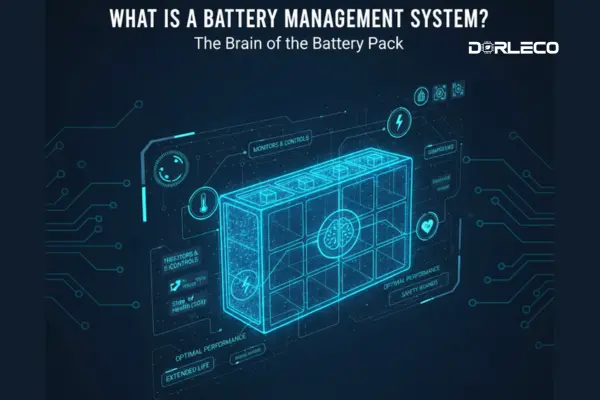

An electrical device called a Battery Management System (BMS) monitors and controls a rechargeable battery to ensure it runs within safe bounds. It is crucial for high-power applications, such as EVs, HEVs, renewable energy systems, and others, where battery life, safety, and efficiency are top concerns. In essence, the BMS serves as the battery pack’s brain, constantly monitoring its condition, preventing it from going beyond its safe bounds, and keeping it in top condition.

Why is BMS Crucial for EVs?

The battery functions as the primary power source in EVs. Because of its great importance, each cell in the pack needs to function at its best. A battery that is not properly maintained may overheat, lose its balance, degrade more quickly, or even provide safety risks such as thermal runaway. Consequently, the BMS of an EV is required to:

- Increased Safety: Prevents issues like short circuits, overcharging, and over-discharging that could result in overheating or fires.

- Extended Battery Life: Reduces battery deterioration by optimizing usage conditions.

- Optimize Range: Assures that the battery operates at its maximum capacity, allowing the car to reach its ideal driving range.

- Monitor Health: Keeps track of the battery’s condition and notifies users when maintenance or replacements are required.

How Does the Battery Management System Operate?

Fundamentally, a BMS gathers information from the battery pack, evaluates it, and then complies with the rules. Let’s overview in more detail:

- Data Collection: Cell voltage, current, temperature, and occasionally other parameters like state of charge (SOC) and state of health (SOH) are all continuously monitored by the BMS.

- Data Processing and Analysis: To ascertain the battery’s present state, the data is analyzed after it has been gathered. For example, the BMS can determine whether the battery is getting close to dangerous operating conditions by examining voltage and temperature information.

- Making Decisions: To maintain a consistent condition, the BMS makes decisions based on its analysis about whether to modify current flows, activate cooling devices, or balance the battery pack’s cells.

- Action: The BMS takes action, such as lowering power flow, activating heating/cooling systems, or notifying the user, if conditions deviate from safe bounds.

Essential Components of a Battery Management System

Generally speaking, a Battery Management System consists of several crucial parts, each with a distinct purpose. Let’s examine the primary components of a typical BMS in more detail:

1. Circuit for Cell Monitoring and Balancing

- Cell Voltage Monitoring: Prevents overcharging or over-discharging by measuring the voltage of individual cells. Maintaining voltages within safe bounds is essential to extending battery life and avoiding thermal problems since batteries are sensitive to changes in voltage.

- Cell Balancing Circuit: The cell balancing circuit makes sure that every cell in a battery pack has the same amount of charge. Because weaker cells deteriorate more quickly than others, imbalances can result in decreased battery life and performance. Balancing circuits distribute the charge among the cells to maintain equal charge levels in the battery pack.

2. Temperature Sensors:

Temperature monitoring is crucial since extremes in temperature can impair battery performance or potentially pose safety hazards. Thermistors or other temperature sensors are commonly used by a BMS to monitor battery pack temperatures and make sure cells are within ideal limits.

3. Current Sensors:

These sensors gauge how much current flows into and out of the battery pack. In addition to preventing overcurrent scenarios that could harm the battery or associated devices, this data is essential for determining SOC and SOH.

4. Microcontroller Unit (MCU)

The BMS’s central processing unit, the Microcontroller Unit (MCU), is in charge of executing algorithms, storing information, and making choices depending on the data that is monitored. It notifies the user, carries out directives such as cell balance, and interacts with other systems or vehicle controls.

5. Communication Interface:

The Battery Management System can communicate with other systems, including the vehicle control unit (VCU) in electric vehicles, by using a communication interface. CAN bus, I2C, and SPI are examples of common communication protocols that enable data exchange for smooth system integration.

6. Safety and Protection Circuitry:

Protection circuitry, which includes features like under-voltage, short-circuit, and overcurrent protection, makes sure the battery runs safely. As a final resort, these circuits guard against disastrous malfunctions.

Essential Features of a Battery Control System

A BMS performs several vital tasks to preserve the safety and health of batteries. Here is a detailed examination of each of these roles:

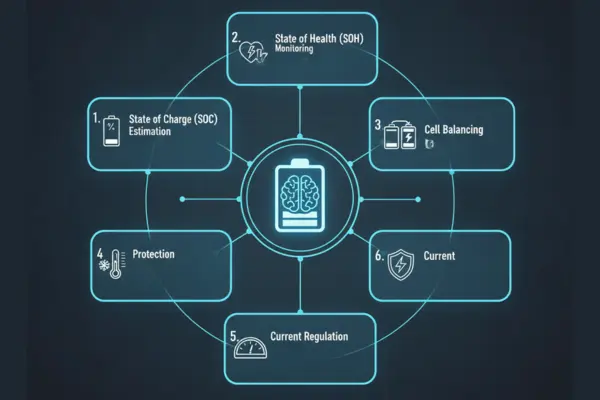

1. Estimation of State of Charge (SOC)

SOC estimate displays the battery’s current charge level as a percentage of its overall capacity. Understanding the SOC is crucial for both energy management and EV range prediction. Temperature and aging complicate SOC calculation, so BMS algorithms use methods like OCV measurement or Coulomb counting for accuracy.

2. State of Health (SOH) Monitoring:

SOH evaluates the general health and remaining lifespan of a battery. It considers things like capacity fading, degradation patterns, and cell resistance. SOH monitoring aids in long-term performance and cost savings by assisting users in determining when maintenance or replacements are required.

3. Cell balancing

As previously stated, cell balancing makes sure that every cell in a battery pack keeps the same amount of charge. Longer battery life and improved efficiency are made possible by this procedure, which stops weaker cells from affecting the performance of the entire pack.

4. Thermal Management:

Because batteries are temperature-sensitive, their lifespan and performance can be impacted by both high and low temperatures. By monitoring cell and pack temperatures and turning on heating or cooling equipment as necessary, a BMS manages thermal management. To maintain peak performance under a variety of circumstances, advanced BMS systems in EVs frequently incorporate temperature management.

5. Protection against Overcharge and Over-Discharge

If someone overcharges or over-discharges a battery cell, it may cause irreparable harm, safety hazards, or decreased performance. The BMS monitors cell voltages and reduces or stops charging if they exceed safe limits.

6. Current Regulation:

The BMS regulates current flow to keep it within safe limits. To avoid overcurrent situations, which can harm battery cells and other system components, this safeguard is crucial.

7. Diagnosis and Communication

Many BMS units log diagnostics like temperature, charge cycles, and trends over time. Furthermore, the BMS can convey data and warnings to other systems via communication interfaces, facilitating remote diagnostics and monitoring.

Keyless Entry and Start Systems: BCM’s Contribution to Security

Challenges in BMS Design and Development

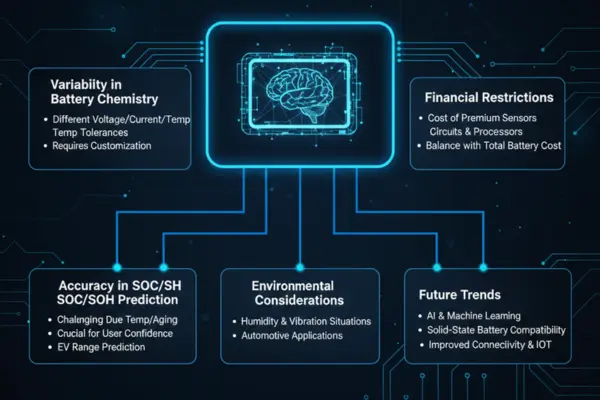

To create a dependable and effective BMS, we must balance several obstacles:

- Variability in Battery Chemistry: Different chemistries have different tolerances for voltage, current, and temperature (e.g., lithium-ion, lithium-iron-phosphate). We need to customize a BMS for the particular battery chemistry.

- Environmental Considerations: Particularly in automotive applications, BMS systems must function in a range of temperature, humidity, and vibration situations.

- Financial Restrictions: You must weigh the price of integrating premium sensors, circuits, and processors into a BMS against the battery pack’s total cost.

- Accuracy in SOC/SOH prediction: Due to variables including temperature, cell aging, and usage patterns, it can be challenging to obtain accurate SOC and SOH readings, which are crucial for user confidence and range prediction in EVs.

Future Trends in BMS Technology

With advancements aimed at boosting efficiency, safety, and accuracy, BMS technology has a promising future. Among the major themes are:

- Artificial Intelligence and Machine Learning: By learning from usage patterns, AI-powered BMS algorithms can enhance SOC and SOH estimations as well as predictive maintenance.

- Solid-State Battery Compatibility: BMS technology will need to advance to accommodate various operating conditions as solid-state batteries proliferate.

- Improved Connectivity and IoT: Cloud connectivity and IoT integration enable real-time data sharing, remote diagnostics, and software updates, which can increase battery life and enhance user experience.

Conclusion

In applications like electric automobiles, battery management systems are essential for guaranteeing the performance, lifespan, and safety of contemporary battery packs. BMS technology will keep developing, providing more safety features, efficiency, and integration as battery technology advances and the need for energy storage solutions grows. BMS technology will become increasingly important in enabling a sustainable future as it advances in sophistication. The BMS is unquestionably the unsung hero behind the scenes, whether it is facilitating EVs’ increased range on a single charge or handling the intricate requirements of renewable energy storage.

Discover how electric vehicle performance will develop in the future with Dorleco’s top-tier automotive solutions! Our blog on Battery Management Systems (BMS) delves into the core of EV innovation, including information on battery longevity, safety, and efficiency—all of which are essential in the rapidly changing EV market of today. At Dorleco, we provide CAN Keypads, CAN Displays, and high-performance Vehicle Control Units (VCUs) for dependable and easy integration with your EV systems. We provide full solutions that maximize performance, minimize downtime, and improve the EV experience when combined with our extensive EV Software Services. Dorleco provides the technologies and know-how to assist you speed up your transition to the future of electric mobility, whether your goal is increasing battery efficiency or EV safety.

Visit us at Dorleco and learn how our cutting-edge solutions can power your next EV project.